Enlarged design documents at development with short delivery time

The company develops embedded software for payment processing, which requires high quality. In recent years, the company has been required to diversify payment methods, increase the complexity of system requirements, and release the software with a short delivery time of about once a month.

In the design document, the contents of the upstream design were duplicated to ensure traceability. In addition, a chapter describing the contents of the change design was added at the time of change development, which was not maintained according to the table of contents, and the system of the design document was broken. Under these circumstances, updates to the design document could not be caught up with by conventional human labor tactics, and there were issues with development efficiency and quality maintenance. Furthermore, the difficulty in tracking changes within the design documents and the unclear connection of deliverables between processes have become barriers to understanding for new and inexperienced members of the team.

Against this background, improving the consistency and traceability of design assets is an important goal in order to respond to rapid development cycles and solve the problem of bloated design documents.

Only one tool for reproducing the design methods you have been using

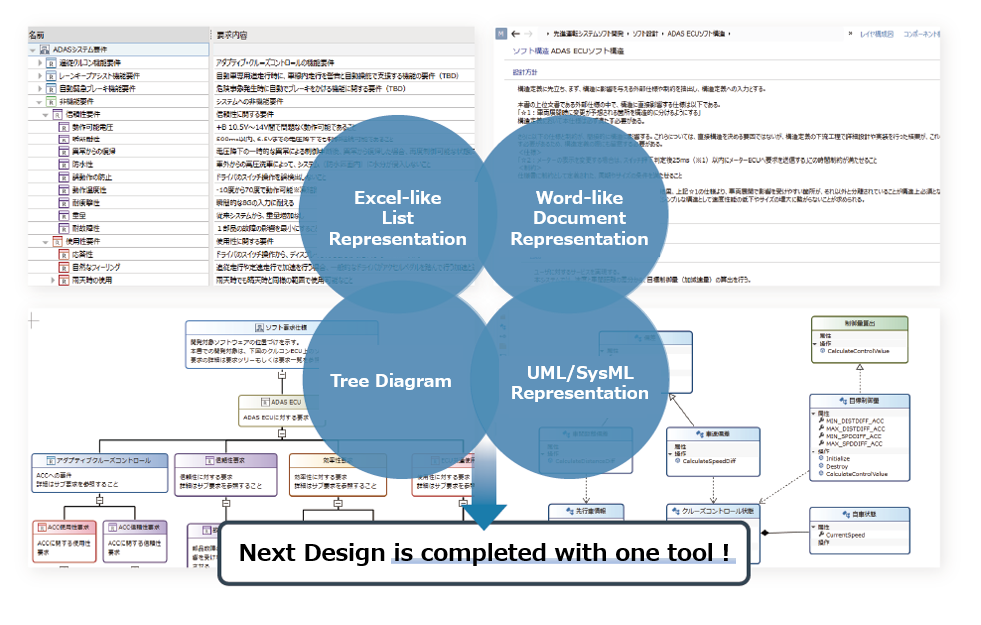

We used a dedicated modeling tool for class diagrams and Word for documentation, and since we were operating by pasting class diagrams drawn with the modeling tool into Word, design information was sometimes inconsistent.

With Next Design, this one tool can be used to customize everything from diagrams to documentation to the way the design documents look today. Next Design allows you to customize and use this tool to match the look and feel of your current design documents from diagrams to documents.

Improved traceability

Since traceability can be recorded automatically while designing, traceability can now be recorded without additional man-hours. Furthermore, since traceability between processes is clearly visible in a dedicated view, the relationship with the design results of the upstream processes is also visualized. This eliminates the need to write down the design results of the upstream processes as references and also eliminates duplication of design information.

Improved consistency of design assets

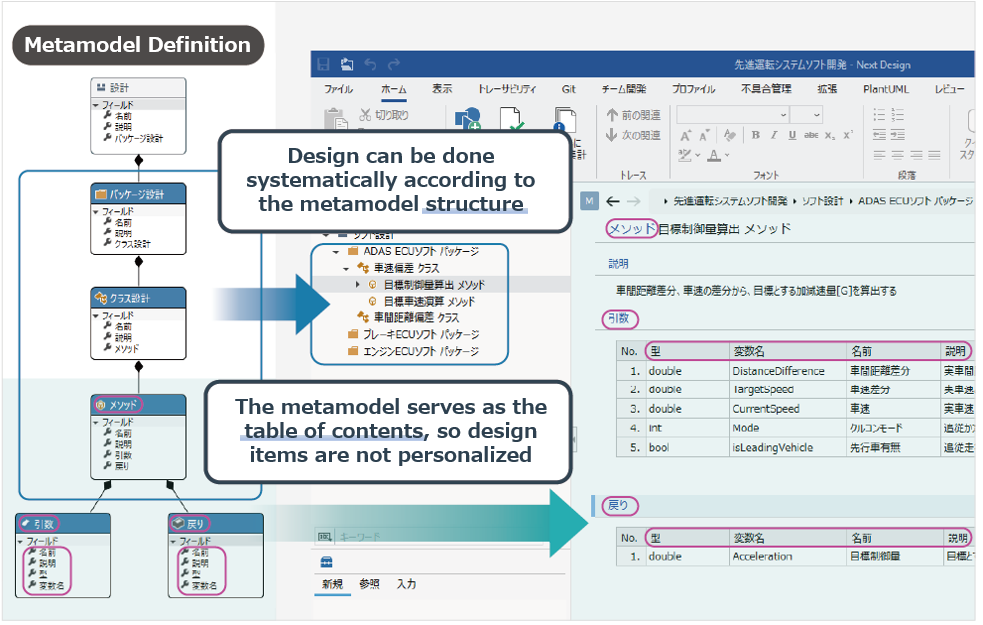

By standardizing and centralizing the design contents in the meta-model, the design contents were systematically organized.

The table of contents automatically displays the contents of the meta-model, thus preventing the creation of a generic structure and maintaining the structure of the design even if derivative development is repeated. This clarified the parts that should be changed at the time of modification.

We want to promote the efficiency of simple, high-load tasks by utilizing digitized design data. We plan to create our own extensions and first automate areas that can be immediately improved, such as filling in review minutes and checking for omissions in design content.

Customer's Voice

Design deliverables that were only textual information are now available at digital transformation!

We were able to customize the modeling tool to meet the needs of the field by designing a meta-model tailored to the business type, which allowed for a smooth introduction to the project. We look forward to future enhancements.

Mr. Goto, Division 2, Nihon Techno Structure Co., LTD.

Back to Achievements